Application in Tooling

Additive manufacturing systems provide solutions for the cost-effective manufacture of molds and tooling. 3D printing has made possible the rapid creation of test molds and inserts in thermoplastic machines for the production of small batches of plastic parts used in real production. It will also be useful for functional prototypes that can be made on site in a matter of hours, using the same technological processes as the serial parts, because now it is possible to print a mold for casting on a 3D printer.

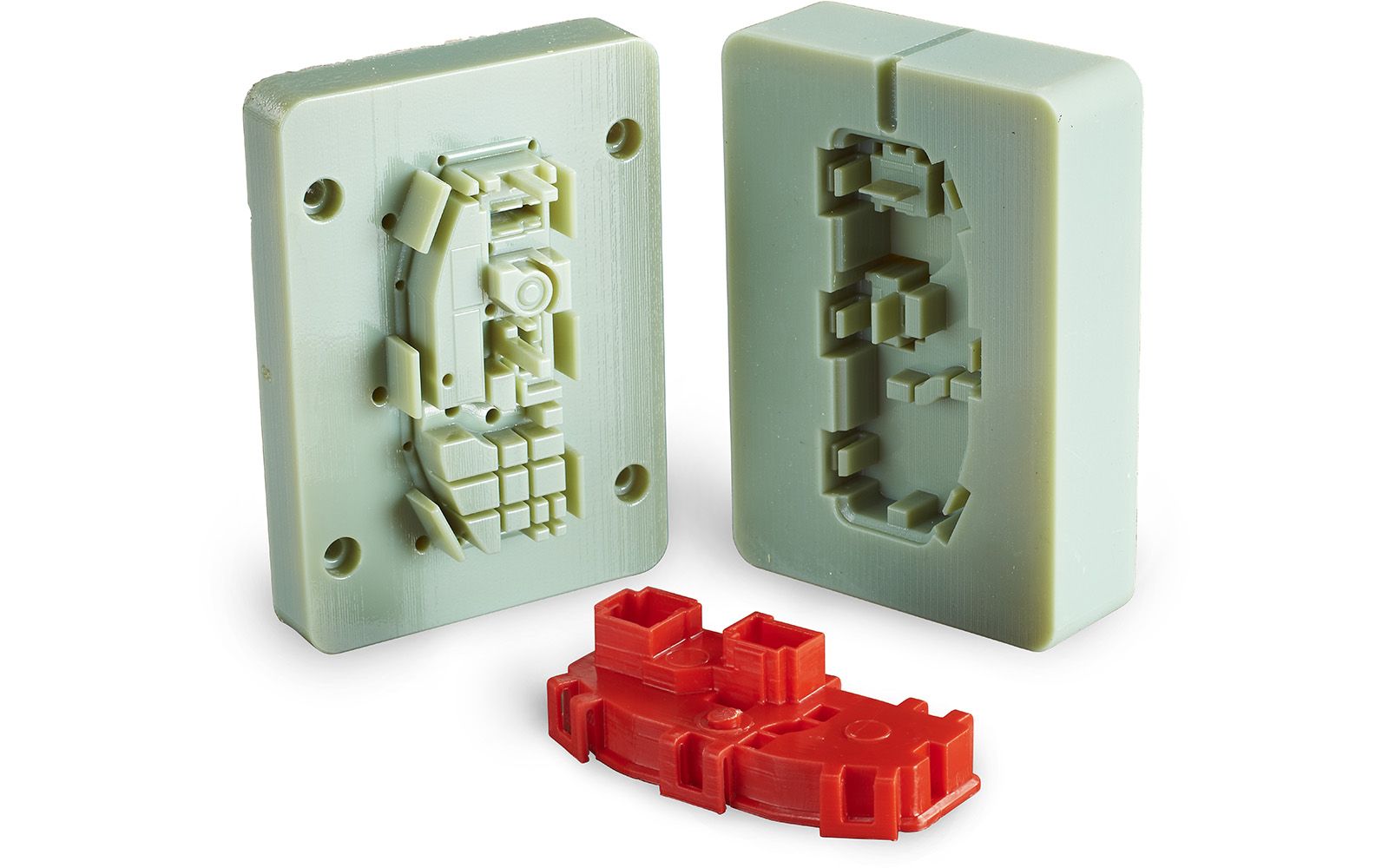

One of the main questions during the design of parts remains the following, whether the 3D printed prototype will lead itself in the same way as the molded part, and for testing it would be better to make a prototype of the same material as the final one. Realizing that the manufacture of equipment from metal for such tasks is expensive and time consuming, Stratasys has developed its own material for the manufacture of test molds, for casting small batches of products. It was successfully tested by Berker to manufacture a small batch of switch assembly parts. As a result, they got their way, and the products were tested, which was spent 90% less time and saved a lot of financial resources. Such technology will be suitable for enterprises with a closed development and production cycle, in order to test the design of a future mold, test the intended design changes, or simply get a batch of products without producing an expensive tooling.

Taking into consideration the availability of additive metal production, some companies already use it to make tooling and molds for casting. The technology of 3D printing with metals allows achieving special design solutions that can not be reproduced by traditional methods. For example, the creation in the mold of cooling channels of complex shape for uniform cooling, which will quickly remove heat from the surface of the mold during the production process and entail a reduction in cycle time and improve the quality of production. 3D printers of this class remove many of the technological limitations and in fact provide space for creativity, both for designers and for developers of model equipment.

English

English  Українська

Українська