Application in medicine

Medicine is one of those areas where the use of 3D printing has given new impetus to larger changes. You no longer need to worry if you will be able to perform an operation on a particular organ, and how it will be done, since it is already possible to scan the necessary area and print it out of materials simulating real ones for testing the operation process and transfer the model to the doctor for preliminary familiarization and conducting test operation on the layout.

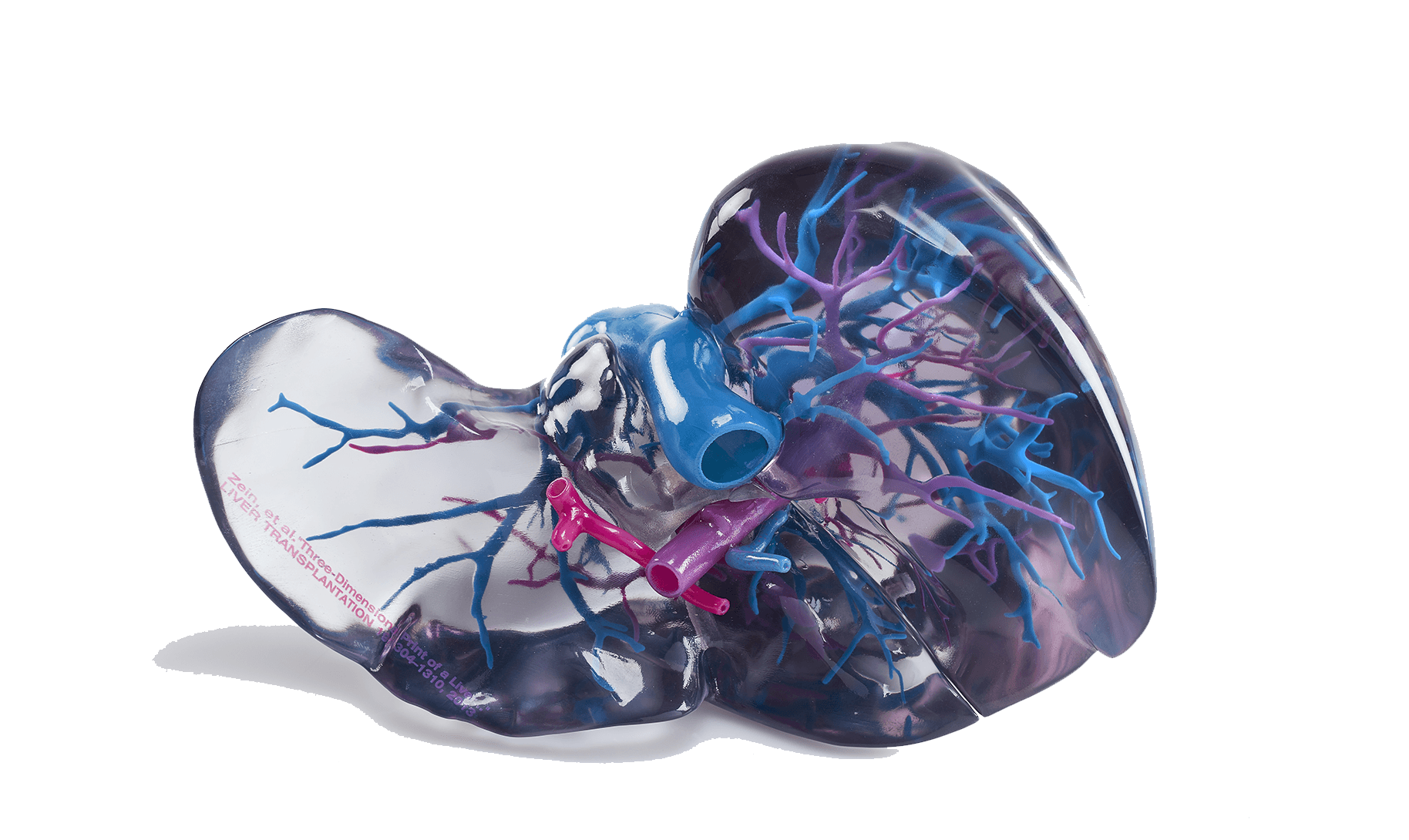

Stratasys with its PolyJet technology has made a great contribution to the development of 3D printing for the medical industry. For several years now, a large number of research centers and clinics have been using their equipment to prevent fatal cases and conduct research. With the help of PolyJet 3D printers are making realistic anatomical models for training, high-precision models for surgical planning, as well as high-quality prototypes for medical devices and instruments.

The Stratasys program - BioMimics, is a tool for the additive production of anatomical models for teaching students, testing promising medical instruments and procedures, as well as preoperative preparation of surgeons. The BioMimics project combines Stratasys proprietary technologies and the expertise of the company's medical consultants to create anatomically accurate mock-ups of various organs that can copy various pathologies and perfectly reproduce tactile sensations, which is important during training.

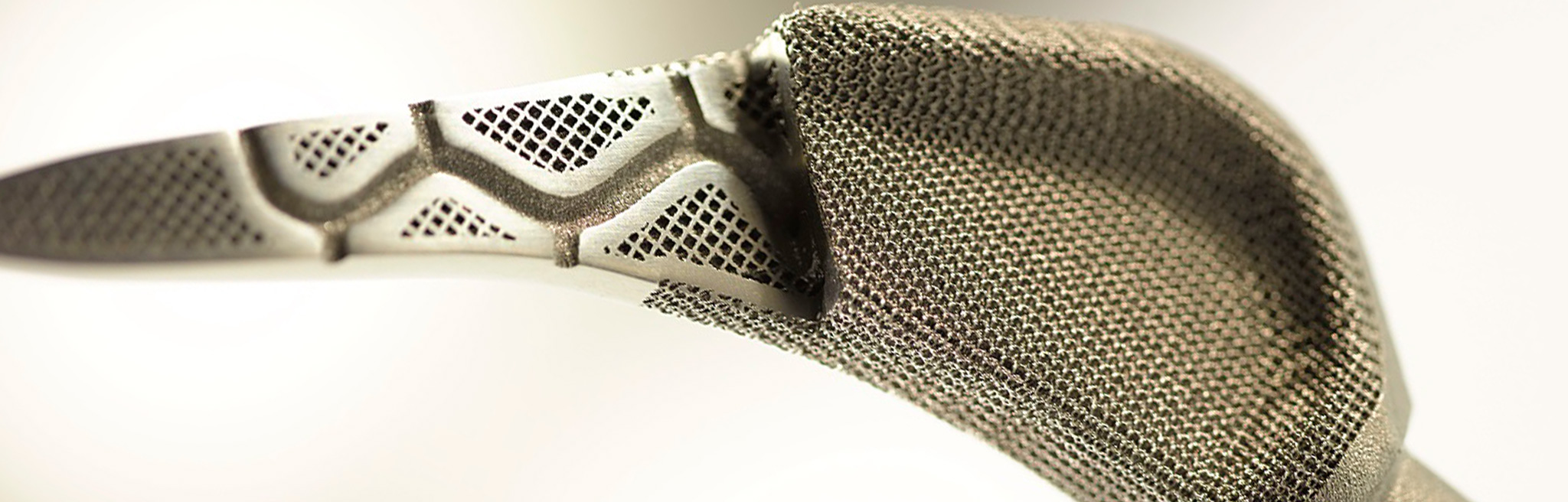

When work requires real metal products of complex shape, experts around the world resort to 3D printing with metals. From the point of view of bone prosthetics, this has a number of advantages, since it is possible to manufacture an individual prosthesis using additive technologies much faster than traditional casting methods, the product is very light in the end, which can also be adjusted and the special porosity allows the prosthesis to “grow over” with living tissue. In the case of the implantation of the knee joints, this greatly simplifies the work of a specialist, as usually prosthesis is selected for prosthetics of the knee joint, after which the bone is ground to approach it. In the case of print, the developers take the results of computed tomography and create a joint that suits the patient as naturally as possible. There are a number of international practices for using 3D printers to create ceramic individual intervertebral cages and cranial implants, which resulted in excellent osteo integration and solution.

English

English  Українська

Українська