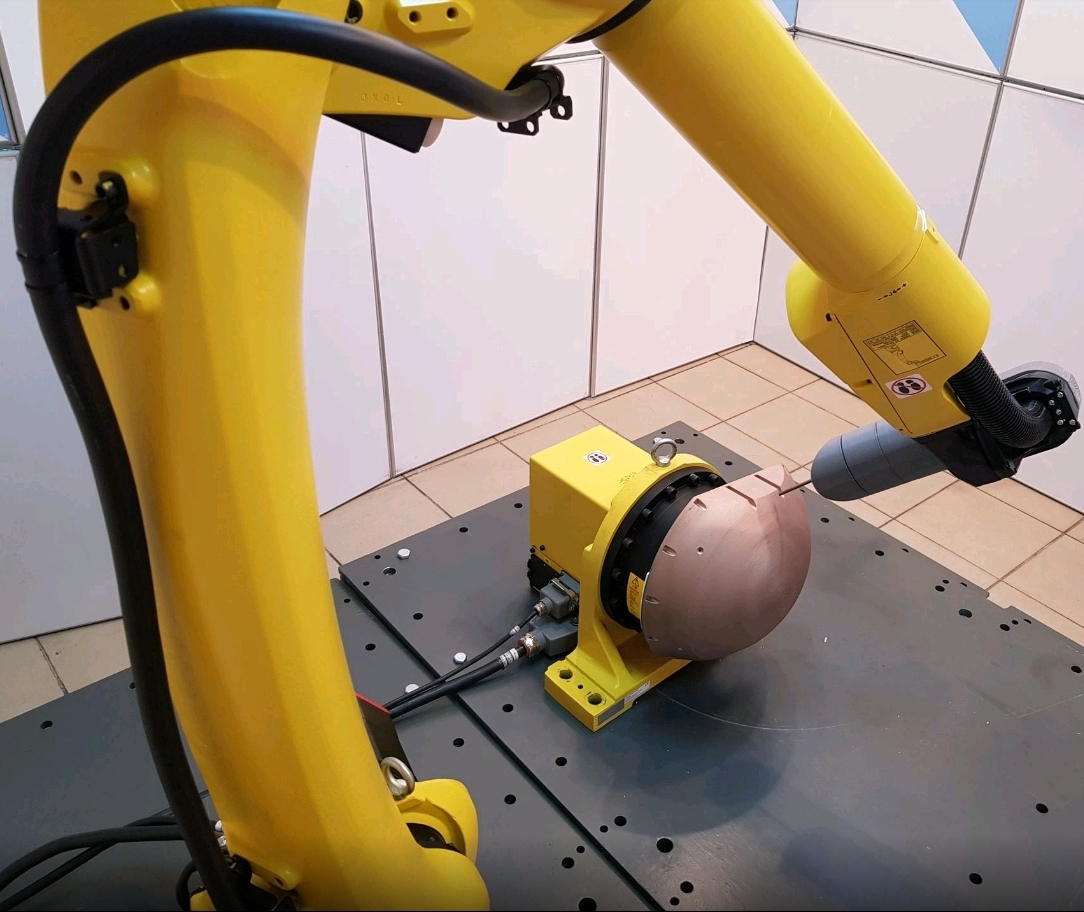

AMS FR is equipment that is installed on Fanuc manipulators for applying various protective coatings and building products using the ProstirJet.

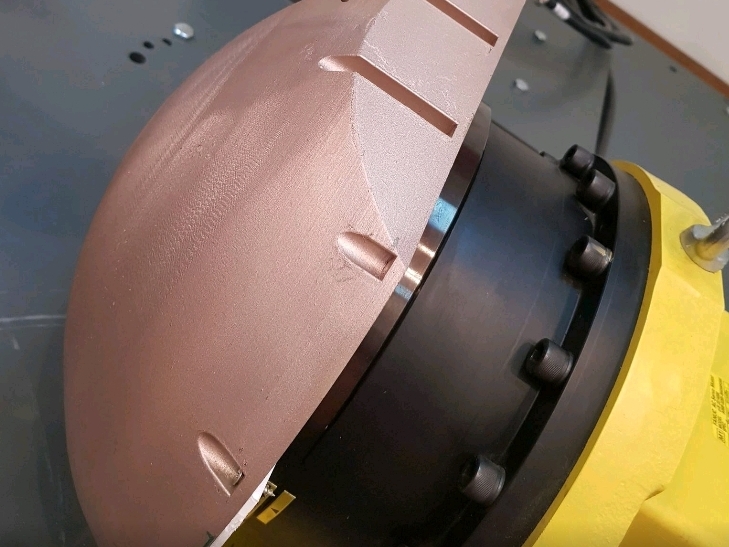

The system is intended for applying combined protective coatings on the surface of finished parts. For cases of electronic equipment - radio-electromagnetic protective coatings. For rubbing surfaces - thermal protective ceramic coatings, etc. The system can be equipped with additional modules for the proper construction and machining of parts from carbon-filled thermoplastics.

AMS FR implements gas-dynamic deposition method - ProstirJet. The advantages of the method are relatively low temperatures in the area of construction of the part, which does not lead to the melting of thermoplastics and oxidation of the metal. The advantages include the possibility of building up structural elements on the parts, the connection of parts from various materials.

Thanks to innovative solutions, the AMS FR system can include several replaceable modules and carry out several technological operations in one production cycle. As a result, you build and get a finished workpiece that cannot be manufactured using traditional production methods.

English

English  Українська

Українська