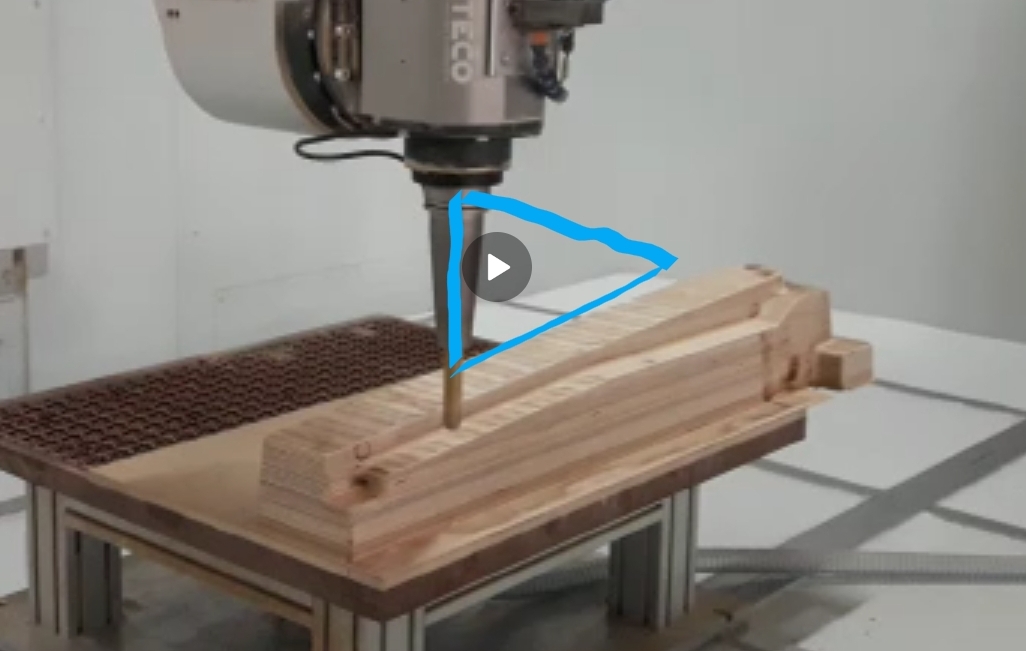

ARES is a five-axis machining center specially designed for high-speed processing of composite materials of light alloys, honeycomb panels. The CMS Ares CNC machine provides high productivity due to its well-balanced structure and powerful workgroup.

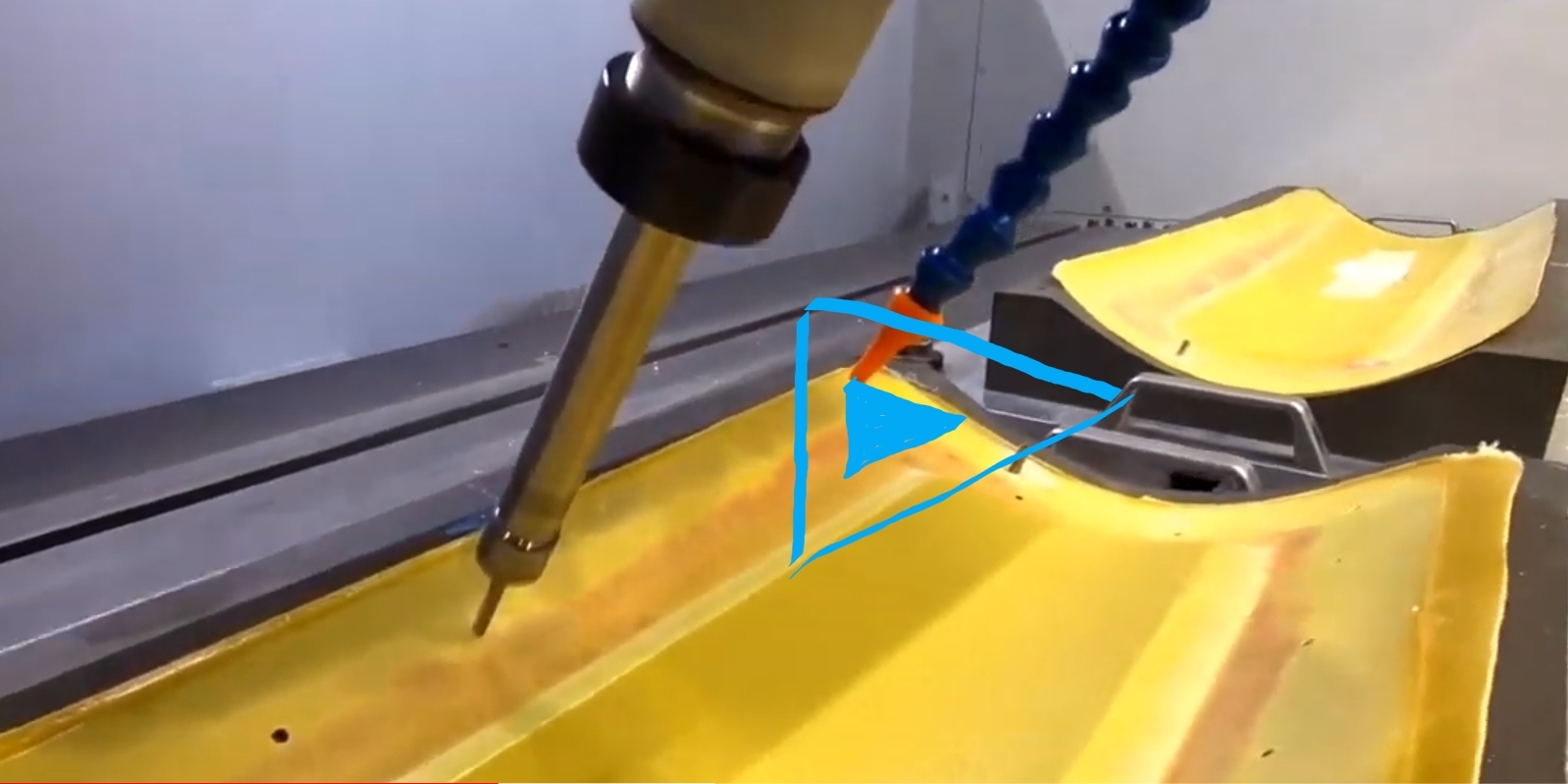

The universal machining center is completed according to customer requirements. CMS Ares can perform various technological operations: milling, drilling, cutting with an ultrasonic knife, measuring with a radio probe. To process a wide range of materials, the machine is equipped with cutting tool cooling systems: oil mist, blowing with cold air, ionization with the removal of static electricity.

.

.  .

.

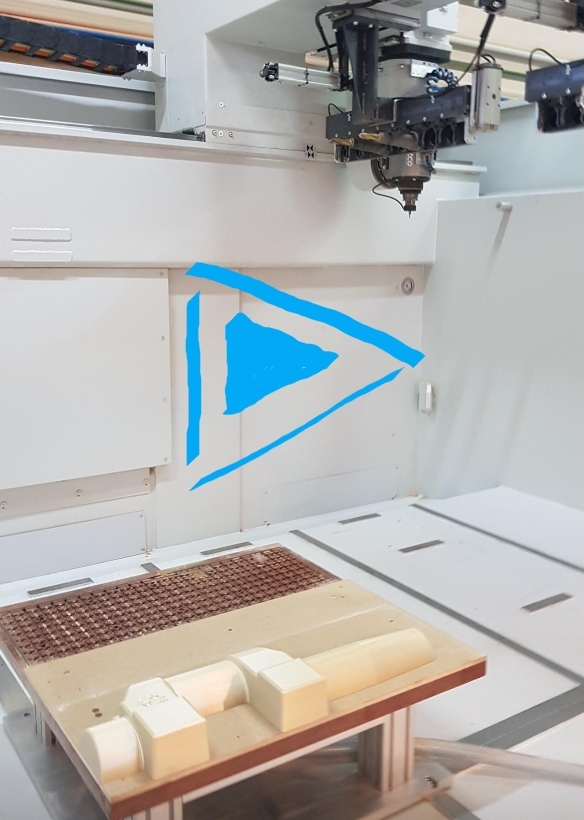

The CNC machine has an advanced structural design that dampens vibrations when processing solid materials and provides excellent surface quality. The well-thought-out ergonomics and innovative design of the Ares machine allow it to harmoniously fit into modern production facilities. The machine has:

Large working area for maximum production freedom;

A wide selection of electrospindles designed and manufactured by CMS; Ability to work in the pendulum mode (one zone or tandem cycle);

High positioning accuracy for the most complex machining operations in the aerospace industry, transport industry, energy.

Adaptive CMS technology is integrated into the production management system, allowing the user to achieve maximum speed of managing technological operations and controlling the results of processing.

The machine can have round-the-clock online support, thanks to new service applications from CMS. All work processes take place inside the cab, which provides the highest level of safety.

English

English  Українська

Українська