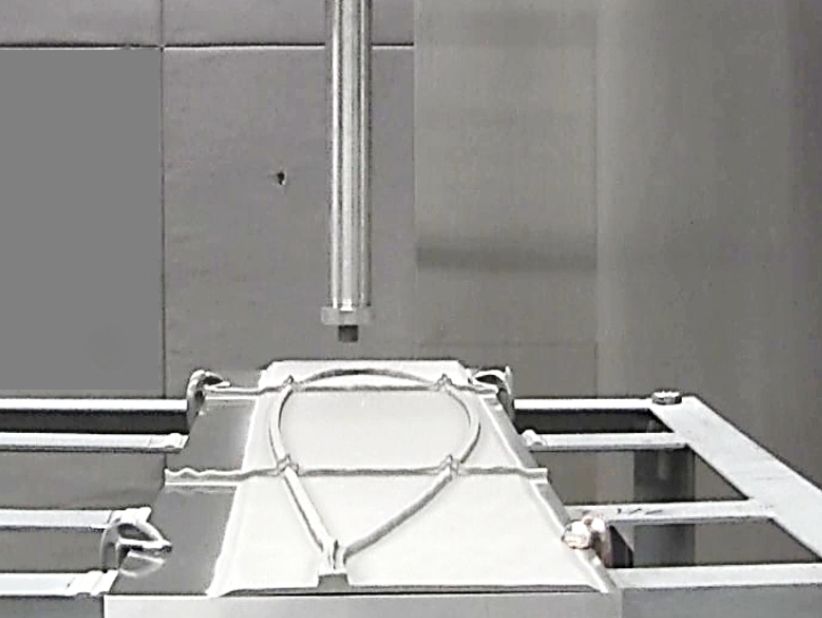

AMS CNC hybrid system is a five-axis machining center with a moving work group and a horizontal work table. The five-coordinate workgroup with the electrical spindle has the ability to install additional units for building products using additive technology.

The pre-fabricated 3D parts are further milled on the AMS CNC machine to obtain the final geometrical dimensions of the part and the required surface quality.

AMS CNC builds parts from metal alloys of aluminum, titanium, copper using the gas dynamic application method - ProstirJet. The advantages of the method are relatively low temperatures in the zone of construction of the part, which does not lead to oxidation of the metal and thermal deformations of the part. The advantages can also be attributed to the possibility of increasing the structural elements on the workpieces, or to restore worn surfaces.

Thanks to innovative solutions, the hybrid 3D system AMS CNC can perform several technological operations in one production cycle. As a result, you build and get ready-made working parts which sometimes cannot even be obtained or restored by traditional production methods.

English

English  Українська

Українська