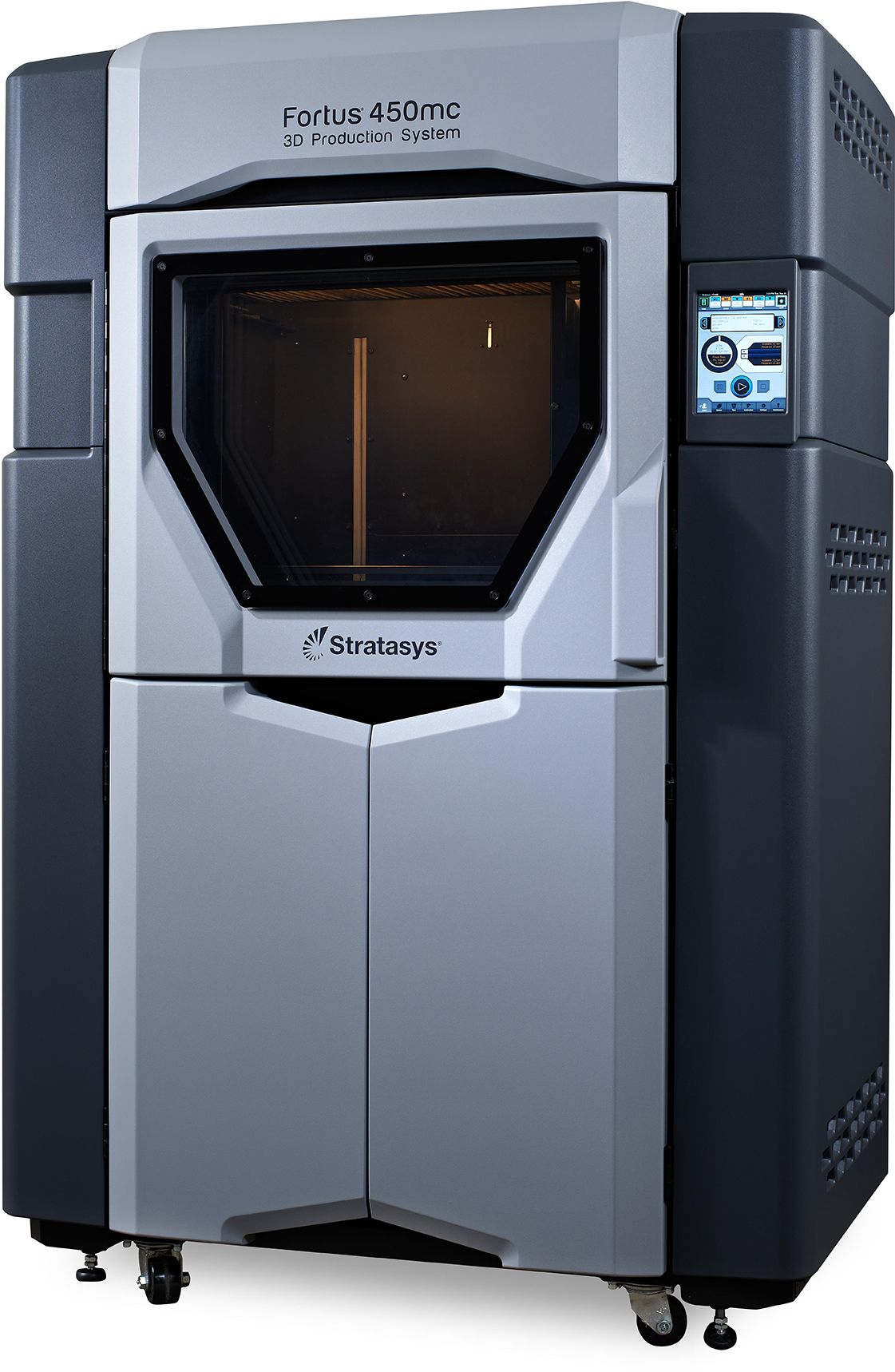

3D printer Fortus 450mc makes it easy to produce mounting elements, various manufacturing fasteners, final parts, as well as functional prototypes that withstand the toughest testing. You can choose from four options for layer thickness and, thus, provide the necessary balance between strength, detail and production speed. The Fortus 450mc system builds complex parts faster than its predecessor, which saves both time and cost. The new generation model has a completely new touch interface for easy operation and maintenance.

This 3D printer uses the most modern high-tech materials certified for the food industry, aviation, there are a number of biocompatible materials, which in turn makes it possible to use this machine in absolutely different industries, such as medicine, engineering, aviation, food industry, instrument making, and so on.

New software GrabCad prepares your STL file for printing on the Fortus system by automatically distributing into layers, forming support structures and material extrusion paths. For maximum control, the user can manually adjust the parameters that determine the appearance, strength and accuracy of the details, as well as the speed and material used in the FDM process.

English

English  Українська

Українська