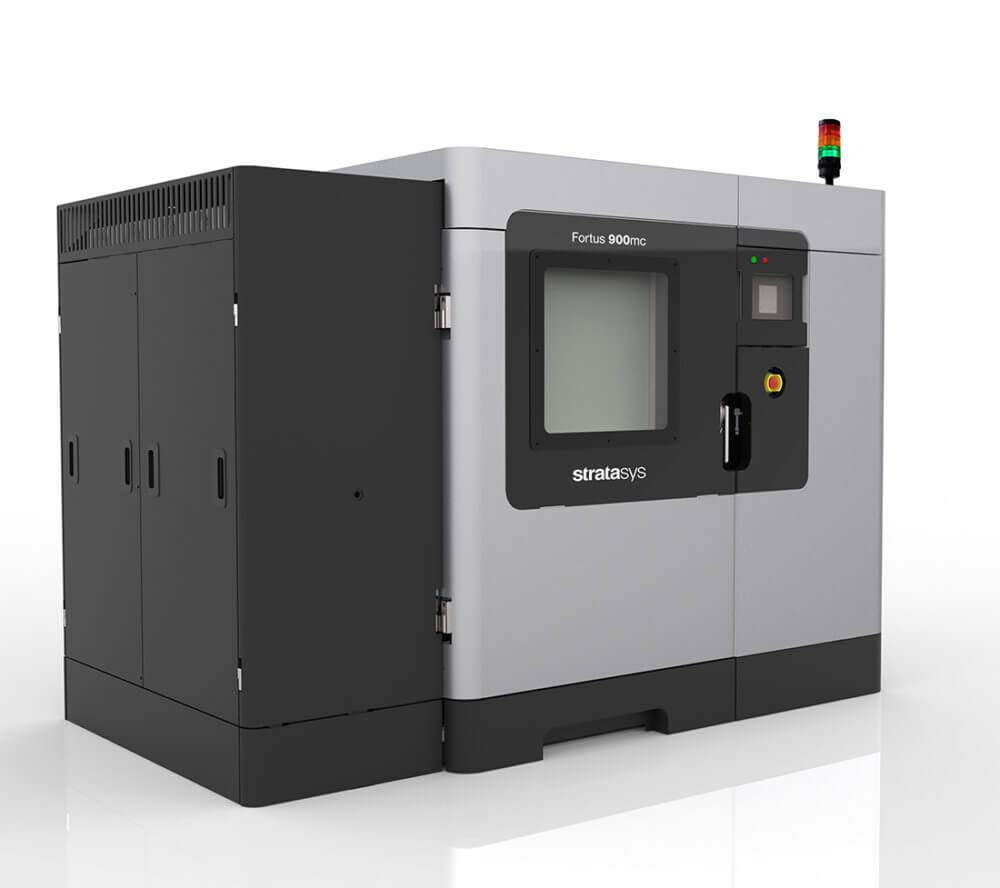

The Fortus 900mc is the most powerful of the available FDM systems; it provides amazing agility, excellent accuracy and high payback. Thanks to the possibility of choosing from a large number of high-quality thermoplastics and a bulk printing chamber, the parts created with this system can only be compared with those produced in the traditional way.

The Fortus 900mc additive manufacturing system allows to create reliable and accurate parts with high repeatability and sizes up to 914 × 610 × 914 mm. Thanks to the use of new high-tech materials, this system is best suited to create fasteners, factory equipment, final parts, as well as the most complex functional prototypes for applications requiring high efficiency, biocompatibility, static dissipation or resistance to heat, chemicals and ultraviolet radiation.

New software GrabCad prepares your STL file for printing on the Fortus system by automatically distributing into layers, forming support structures and material extrusion paths. For maximum control, the user can manually adjust the parameters that determine the appearance, strength and accuracy of the details, as well as the speed and material used in the FDM process.

English

English  Українська

Українська