Application in aviation

Since the first glider of the Wright brothers, which was launched in the 1900s, the technology of aircraft building has improved significantly, making international flights and space exploration a reality. Aerospace industry includes a number of commercial, industrial and military applications and consists of departments that design, produce, operate and maintain aircraft or spacecraft. Being the first supporter of 3D printing, the aviation has become a driving force in the evolution of this technology, both for the production of end-use products and for prototyping. Additive manufacturing, better known as 3D printing, plays a significant part in this revolution, due to the reduced weight of fabricated parts, high strength of materials and the possibility of optimizing the design without any production restrictions.

In fact, minimizing weight allows manufacturing companies to reduce costs, as weight affects payload, fuel consumption, emissions, speed, and even safety. Unlike traditional manufacturing processes, such as CNC, where material is removed to get the right part, the 3D printing technology of Stratasys FDM (Fused Deposition Modeling) creates a part by layering overlay molten plastic strands, allowing creating complex surfaces and producing simplified construction with less total amount of components - all this leads to weight reduction in flight. More than 1 thousand parts of the Airbus A350 XWB were printed on a 3D printer, so this aircraft has more parts made by using this technology than any other one. This technical experiment initiated the use of 3D printing for civilian airliners, as before this technology was used only for military aircraft.

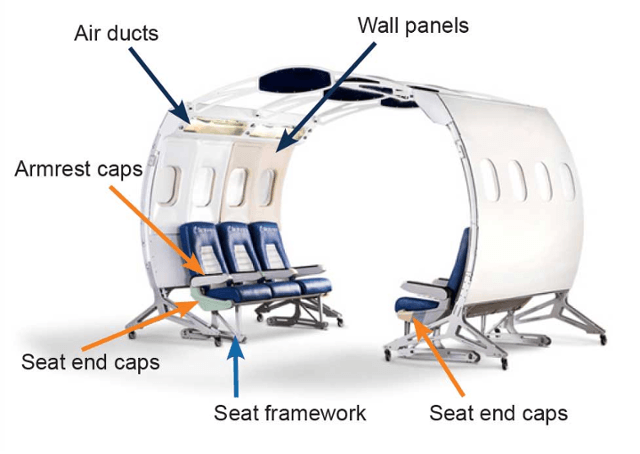

Air ducts, wall panels, seat frames, and even engine components — all of these parts received weight reductions provided by 3D printing. Certification of Stratasys materials for use in aviation allowed manufacturers not to waste time approving material, but made it possible to receive finished products directly from the printer. Materials Ultem1010, Ultem9085 - one of the most used materials in aviation, which are used on FDM 3D printers.

Industrial giants such as Boeing, General Electric, Lockheed Martin are already actively interested in and use these technologies in their production to reduce delivery times and the cost of finished products. Cost effectiveness and practicality - two qualities that should be duly appreciated and as a result, the industry will only grow.

English

English  Українська

Українська