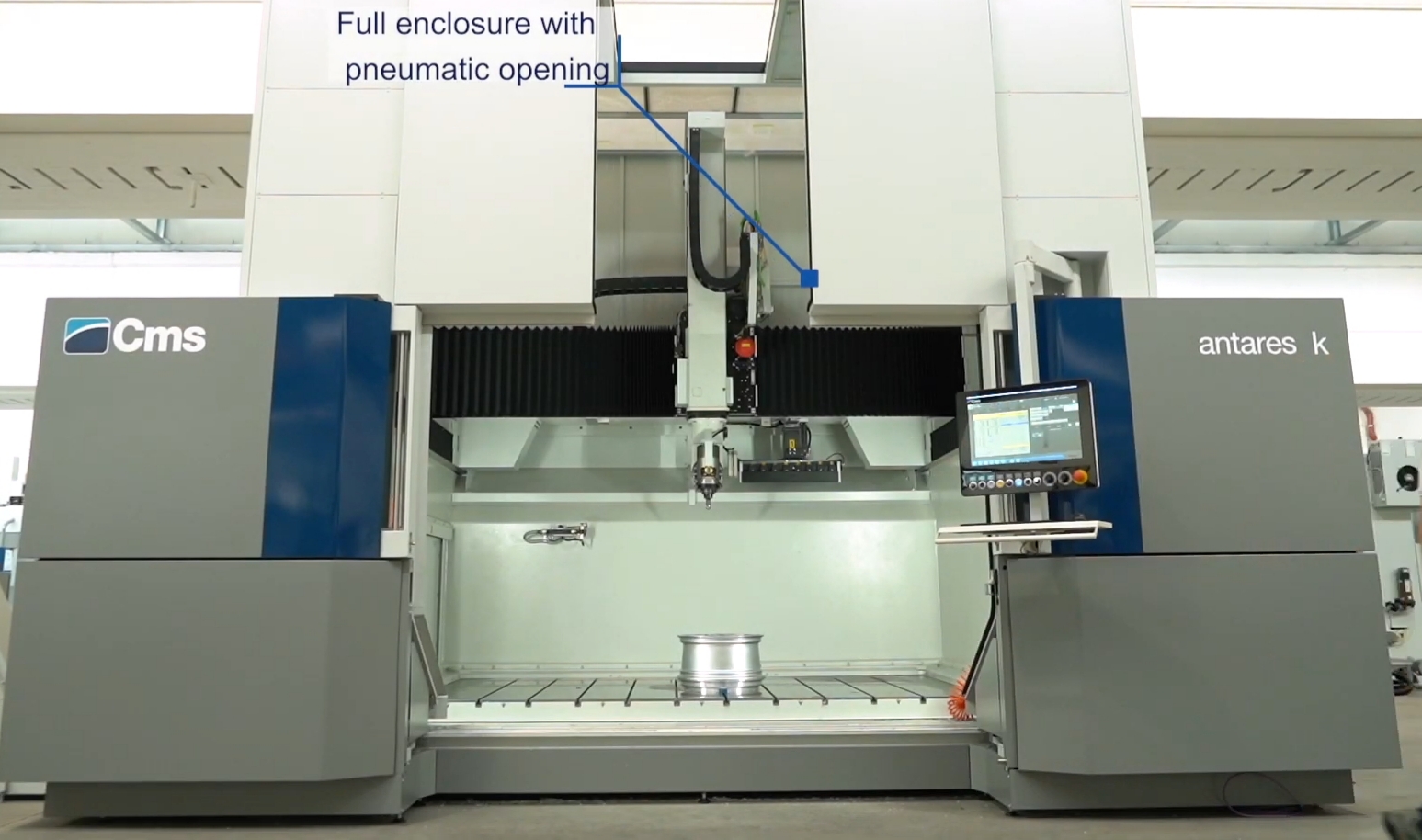

ANTARES K machining center is a high-speed five-axis milling center for machining alloy metals. The milling group is equipped with a high-speed electric spindle with increased power and a tool cooling system through the spindle shaft.

The machine is built according to the classical scheme, with a movable working bridge and two rotary axes on the working group. For harsh machining modes, the rotary axes are equipped with a pneumatic interlock. The machine has a reinforced monoblock bed, a cast-iron work table, and a liquid cutting tool cooling system. Chip conveyor. The security system includes a closed cabin around the perimeter of the machine, with automatic sliding doors. The purpose of the machine is high-speed processing of alloy metals. Scope - aviation and automobile industry, mechanical engineering.

ANTARES K includes two models with a working table 2600x1700mm and 2600x2800 mm. Z axis - maximum machining height, for both models is 1200 mm. Tool magazine with 8 positions, located on a movable traverse, two revolving magazines with 24 positions each, mounted on a bed. The five-axis working group is equipped with a spindle, liquid-cooled, with a power of 20 kW, and a rotation speed of 0 to 24,000 rpm.

CNC system - SIEMENS or FANUC, according to the decision of the customer.

The ANTARES K 2618 machine was first introduced by CMS at the international exhibition EMMO 2019..

English

English  Українська

Українська